Granite, known for its durability, natural beauty, and versatile applications, is a widely used stone in construction and interior design. But have you ever wondered about the journey granite takes from the depths of the earth to your kitchen countertop or the facades of iconic buildings? In this blog, we will delve into the fascinating world of granite quarry processes, shedding light on the intricate steps involved in extracting, processing, and bringing this stunning natural resource to life.

Step 1: Geological Exploration

Experts study the earth’s crust to identify areas with granite deposits. These areas are meticulously surveyed, and once a suitable deposit is located, the quarrying process can commence.

Step 2: Site Preparation

Preparation involves clearing vegetation and the layer of soil and rock that covers the granite deposits. This process ensures access to the desired granite bedrock.

Step 3: Drilling and Blasting

Once the site is prepared, the next step involves drilling holes into the granite using specialized equipment. Explosive charges are then strategically placed in these holes to blast apart the granite. This process breaks the granite into manageable pieces that can be extracted.

Step 4: Extraction

The granite blocks created through blasting are extracted using cranes and loaders.

Step 5: Transport

The extracted granite blocks are loaded onto trucks and transported to processing facilities or storage yards.

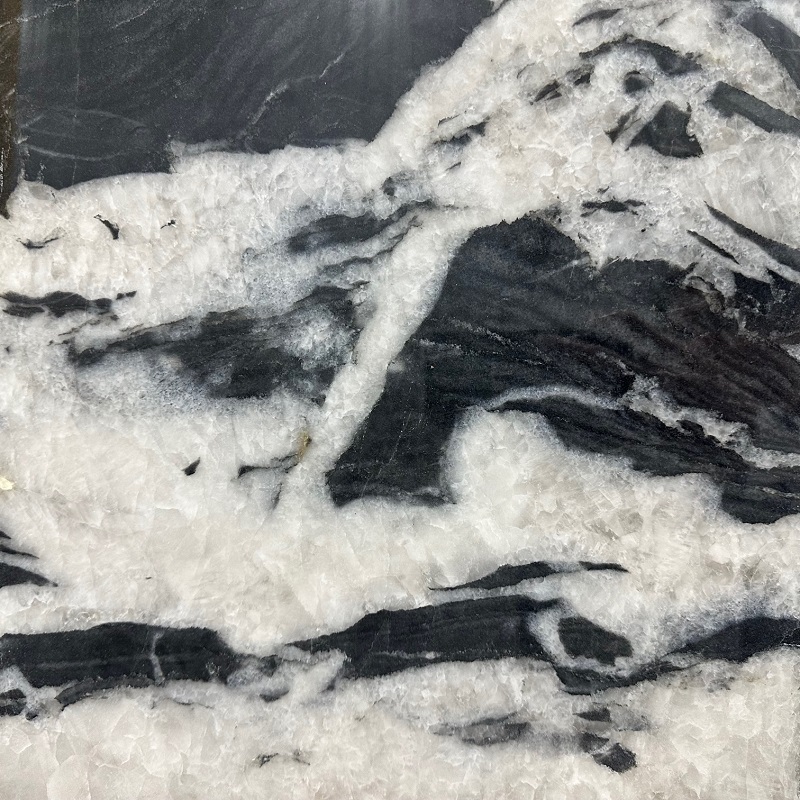

Step 6: Cutting and Shaping

At the processing facility, the granite blocks are cut and shaped into various products. This step is a combination of art and science, with skilled craftsmen using diamond-tipped saws and other precision tools to create slabs, tiles, and custom pieces according to specifications.

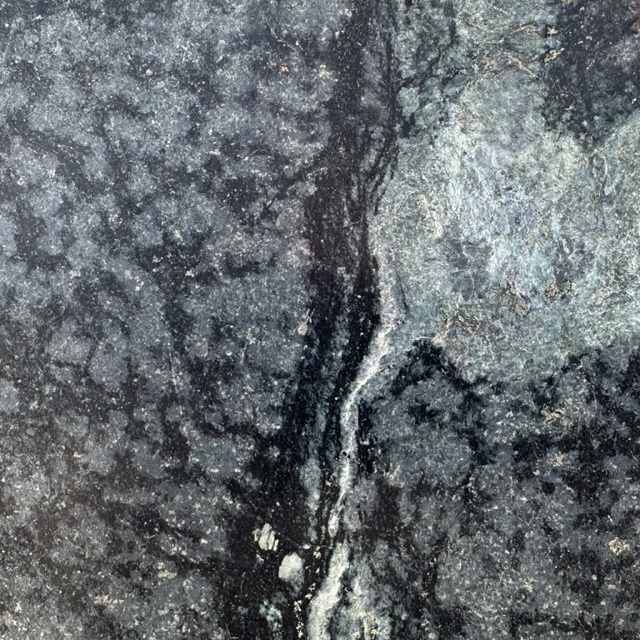

Step 7: Polishing

After cutting, the granite surfaces are polished to reveal their natural luster and rich colors. This enhances the stone’s aesthetic appeal, making it ready for use in a variety of architectural and design applications.

Step 8: Quality Control

Before the granite products are shipped to their final destinations, they undergo rigorous quality control checks to ensure the stone meets industry standards for strength, color consistency, and appearance.

Step 9: Distribution

Once the granite has passed quality control, it is distributed to suppliers, manufacturers, and construction projects worldwide.

The journey of granite from quarry to its final destination is a fascinating process that combines science, artistry, and precision. Granite quarry processes involve geological exploration, site preparation, drilling, blasting, extraction, transport, cutting, shaping, polishing, quality control, and distribution. This natural stone’s journey reflects the skill and dedication of those involved in the granite industry and its enduring appeal in architecture and design. The next time you admire a granite countertop or the exterior of a grand building, you can appreciate the incredible journey the stone has undertaken to become a part of our lives.