Pompeii, the ancient Roman city buried by the eruption of Mount Vesuvius in 79 AD, is renowned for its extraordinary preservation of daily life, art, and architecture. Among the well-preserved features are the splendid natural stone countertops that adorned the homes of Pompeii’s prosperous citizens. These countertops, crafted from materials like marble and granite, serve as a testament to the enduring allure and functionality of natural stone in interior design.

The ancient Romans were masters of engineering and design, and their choices in materials were a testament to their sophistication. Natural stone countertops were highly favored in Pompeii for several reasons:

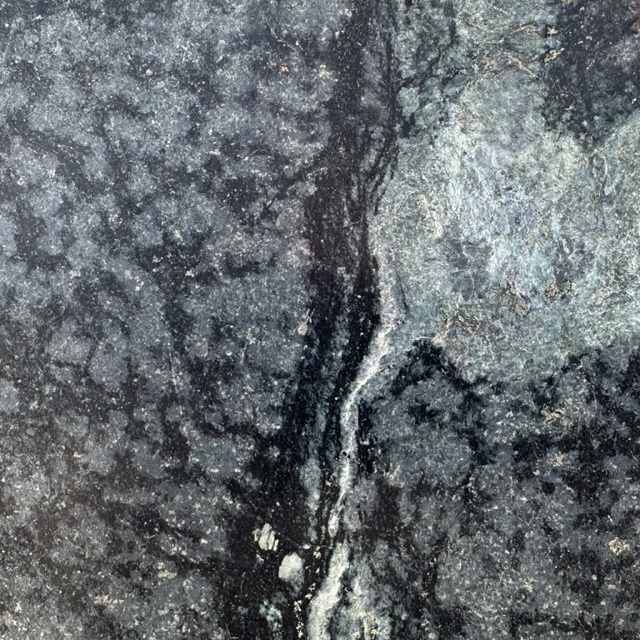

1. Aesthetic Grandeur: Natural stone countertops in Pompeii were often crafted from marbles like Carrara, which boasted exquisite veining patterns and a luminous surface. These countertops added a touch of opulence to the homes and reflected the social status of their owners.

2. Durability: The eruption of Mount Vesuvius buried Pompeii for centuries, and yet the natural stone countertops remained remarkably intact. This enduring quality testifies to the robust nature of these materials, which can withstand the test of time and the rigors of daily life.

3. Hygienic Properties: Natural stone easier to clean and maintain than other materials available at the time, making it an ideal choice for countertops. In an era where hygiene was of utmost importance, natural stone surfaces contributed to a healthier living environment.

Natural stone countertops have a long history throughout the world, and our own modern selection choices are made with the same priorities as ancient peoples. The durability, aesthetic features, and timeless elegance of natural stone endures through time all the way from 79 AD to today.

Contact Exquisite Stone today for timeless countertop options!